Plasma Bioengineering

The Plasma Bioengineering department bundles the competencies in the procedural development of processes that are based on the interaction of plasma with biological material. To this end, competencies are maintained in the development, coordination and diagnostics of plasma sources that are optimized for the task, as well as in the diagnostics of the biological systems that are dealt with. In addition, the derivation and optimization of the required process development is another focus area.

Current thematic focus areas are development of plasma processes for hygienization in the post-harvest area with an emphasis on the food sector, as well as innovative methods for process analysis and process monitoring.

Examples of the current activities of Plasma Bioengineering Department include

- Development of a hygienization procedure based on reactive nitrogen species (RNS) that enables dry treatment, as well as wet treatment with one basic device.

- Development of optical sensors for process monitoring based on special diode laser systems.

Application-oriented research work occurs predominantly on the basis of joint projects with considerable industry participation.

Technological equipment

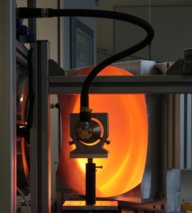

Single Stage PLexc (SSP)

Single stage, self-igniting, atmospheric microwave-regulated plasma torch for RNS process gas generation (Plasma Processed Air – PPA) with process control for operation of peripheral devices, capacity: 12 slm

Auxiliary Decontamination Unit (ADU)

Dual-stage, self-igniting, atmospheric microwave-regulated plasma torch for RNS process gas generation (Plasma Processed Air – PPA) with process control for operation of peripheral devices, capacity: 100 slm

Basic Research PLexc (BRP)

Dual-stage, self igniting atmospheric microwave-regulated plasma torch for RNS process gas generation (Plasma Processed Air – EPA) with process control for investigation of fundamental process management issues, equipped with various measurement technologies (see below).

Units for generation of plasma treated water (PTW)

Total capacity 2000 l

Various peripheral devices for dry and wet treatment

... for dry and wet treatment of bulk goods, fruit and vegetables, as well as meat products in batches of up to 200 kg.

MinMIP

Small microwave-excited plasma torch for chemical diagnostics and biological applications

Microbiological standards

- Proliferation assays

- life-death determination

- biofilms

- RG1 and RG2 microorganisms

Standard methods of quality monitoring

- Water content

- sugar content

- color changes (lab system)

- Vitamin C determination

- Texture analysis

Optical measurement technology

- Optical emission spectroscopy (OES)

- Fourier-Transform-Infrared spectroscopy (FTIR)

- Thermometry

- Laser diode absorption spectroscopy

- Fluorescence microscopy

High frequency measurement technology

- Spectrum and Vector Network Analysers

- Microwave interferometers