Plasma-Printing & Microfabrication

The Research Group Plasma Printing & Microfabrication (PPM) focuses on the development and characterization of novel functional layers and innovative surface modification processes using atmospheric pressure plasmas, particularly at the sub-millimetric scale.

Plasma-assisted surface modification processes enhance material properties by introducing new surface functionalities and by either depositing or removing thin layers. These plasma surface treatments offer several technical advantages, including scalability, long-term stability of modified surfaces, compatibility with a wide range of materials, rapid processing times, environmentally friendly techniques, and the ability to generate numerous functional groups. Consequently, the applications of these techniques are vast and varied.

Within the PPM Research Group, we explore the production of thin plasma-polymer (pp) and composite coatings at both macro and micro scales, emphasizing an interdisciplinary approach that bridges plasma technology, process development, polymer chemistry, and materials science. A key focus is the research and development of plasma-based tools and processes for maskless, high-resolution surface modification, particularly plasma printing, with applications in various fields. One significant area of exploration is the creation of functional surfaces for biomolecule coupling intended for biosensors, cell applications, and microfluidics in the life sciences sector (including medicine, pharmaceutical applications, and biotechnology). Additionally, we investigate plasma-based surface modifications for electronics, semiconductors, microfabrication, and the development of new materials. We also prioritize the identification of safer and greener precursors for producing pp films under ambient conditions, the synthesis of thin hydrogel layers, the creation of tailored periodic structures, and the micro- and nanostructuring of various materials (such as metals, polymers, paper, and fibers) using atmospheric pressure plasmas.

The properties of these generated layers and modifications are examined using advanced surface analysis techniques, providing insights into layer structure and stability based on the coating or removal process used.

Technological equipment

Plasma Printing and Plasma-Assisted Microfabrication

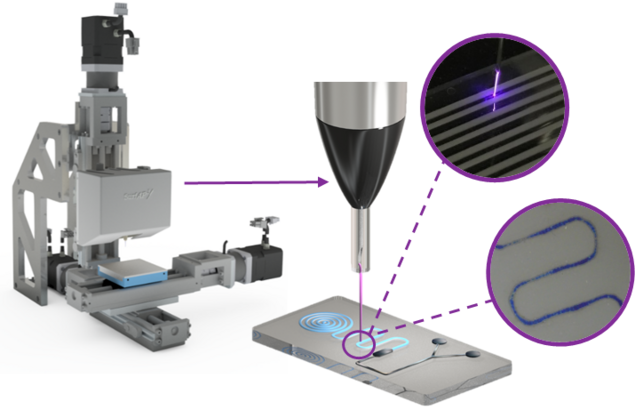

The PPM Research Group has developed and optimized proprietary plasma printing equipment and processes in collaboration with other research groups at the institute. Key innovations include a micro atmospheric pressure plasma source known as MicroPulsar and the Surface Atmospheric Pressure Plasma Printing (SurfAP3®) technology. This cutting-edge process allows for site-selective deposition of plasma polymer, metal, and composite coatings, as well as surface modifications with structural dimensions ranging from 35 to 500 μm, all facilitated through the MicroPulsar plasma jet-based source.

MicroPulsar is a state-of-the-art direct writing tool capable of treating both conductive and non-conductive substrates with high efficiency and low operational costs. It is scalable, modular, and can be OEM-compatible upon request, making it adaptable for various applications beyond plasma printing, such as medical technology, research, and new materials development.

Through the use of MicroPulsar, SurfAP3® and several plasma printers, we enable plasma-assisted microfabrication and plasma-based additive manufacturing at atmospheric pressure, suitable for a wide range of applications including microelectronics, flexible electronics, semiconductors, heterogeneous integration, life sciences, sensing technology, in-space manufacturing, optics/photonics, cosmetics, and more.

Atmospheric-pressure plasmas for functional coatings

Thin plasma-polymerized (pp) films and composites, including thin hydrogel- and periodic structure-layers, are produced using different atmospheric-pressure plasma reactors, yielding layers with thickness ranging from nanometers to a few micrometers, and lateral size from micrometers to centimeters. The plasma-based crosslinking or curing of different precursors, for example to generate coatings enriched with oxygen-containing functional groups, or conductive layers, is possible. Investigations into the chemical composition, morphology and stability of the plasma-polymerized films in aqueous environments and other testing setups are conducted to examine their functionality and validate them for industry-related applications.

Surface characterization and sensing equipment

The properties of the generated layers and modifications are investigated using a variety of surface analysis methods to obtain insights into the layer structure and stability based on the coating or removal process used. Some of these methods include: AFM, AFM-IR, SEM, XPS, profilometry, FTIR, water contact angle, white light interferometry, and optical ellipsometry.

Equipment for the research and development of biosensing surfaces includes: quartz crystal microbalance, electrochemical equipment (such as scanning electrochemical microscopes and potentiostats), a surface plasma resonance system, as well as basic microfluidic equipment, among others.

Contact

Dr. Laura Barillas-Mora

Management Plasma-Printing & Microfabrication

Phone: +49 3834 554 3802