Plasma Surface Technology

The Department for Plasma Surface Technology bundles years of experience in development of plasma-assisted processes for modification of surfaces for applications, as well as in the high-tech sector, e.g. automobile, aeronautics, optics, microelectronics, tool manufacturing and in the life science sector, e.g. implants, biosensors, food industry, biomedical products.

The expertise includes

- Modification of metals, ceramics, glass and polymers

- Surfaces with photo-catalytic effect

- Scratch resistant surfaces

- Wear protection

- Corrosion and oxidation protection

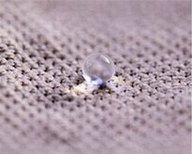

- Hydrophilic/hydrophobic surfaces

- Biocompatible surfaces

- Cell adhesive/sell anti-adhesive surfaces

- Antimicrobial surfaces

- Textile treatment

- Modification of plastic surfaces

- Development of atmospheric pressure plasma sources for layer deposition

- Plasma electrolytic fine cleaning, polishing and deburring

Properties of materials and interaction of materials with their environment are primarily determined through the surface condition. With the aid of plasma technology it is possible to selectively modify virtually any surface property, and in this manner produce a new generation of material surfaces with special functions. Surface analysis is one of the special areas of INP. The existing spectrum of measurement apparatus, operation skills, as well as the methodology for evaluating the measured data is continuously extended and improved.

Technological equipment

Plasma processes under low pressure and normal pressure conditions

In this regard various plasma processes under low pressure and normal pressure conditions are used and theses processes being consistently further developed. Equipment in the laboratory and equipment on an industrial scale are available for this.

- Processes in DC plasmas, DC-pulsed, high-frequency plasmas. and microwave plasmas

- Ion implantation (PIII and PIII)

- Magnetron sputtering

- High Power Impulse Magnetron Sputtering (HiPIMS)

- Plasma spraying

- Plasma electrolytic polishing, deburring and fine cleaning

- Plasma-Enhanced Chemical Vapor Deposition (PECVD)

- Surface modification via atmospheric pressure discharges (DVD, plasma jet)

Use of a number of surface-analytical methods, such as XPS, REM, STEM, EDX, XRD, profilometry, and FTIR, together with a large pool of plasma diagnostics, such as FTIR, OES, Langmuir, and energy-selective mass spectrometry, enable development of high-quality processes for modification of surfaces for different application areas.

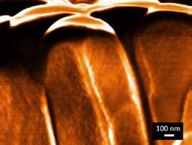

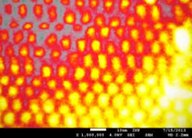

Analysis of topography and morphology

- High-resolution scanning electron microscopy (HR-SEM)

- Scanning transmission electron microscopy (STE M)

- Atomic force microscopy (AFM)

- Profilometry

- White light interferometry

- Light microscopy with 3D function

Determination of chemical composition, binding and structure

- High resolution x-ray photoelectron spectroscopy (XPS)

- Energy-dispersive x-ray spectroscopy (EDX)

- X-ray diffractometry (XRD)

- FTIR spectroscopy

Determination of wear-resistance

- Abrasion test

- Multi-layer transverse-section method

Investigation of mechanical properties

- Microindenters

- Nanoindenters

Determination of contact angle and surface energy

- Contact angle measurement devices

Determination of the optical properties

- UV-VIS spectrophotometry

- Optical ellipsometry

More information at: