Surfaces & Materials

Plasmas are an indispensable tool for material synthesis and targeted surface modification. They can impart additional new properties to materials and allow the complete modification of the interfacial properties of components.

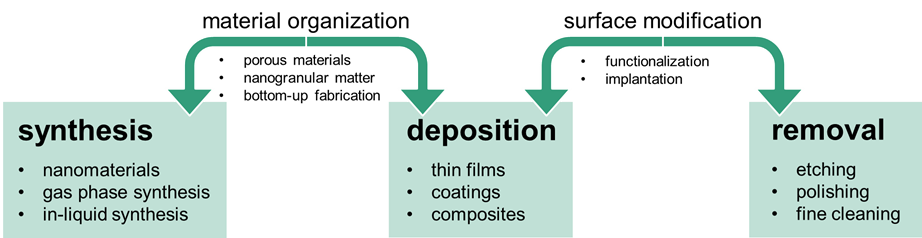

The research program Surfaces and Materials explores plasmas under low pressure and atmospheric pressure conditions to create materials with tailored material and surface properties. Bundling competencies in surface modification, thin film deposition and material synthesis based on low-temperature plasma technology, the research program designs customized solutions for the implementation of socially highly relevant topics such as energy materials, bioactive surfaces, biosensors as well as sustainable surface treatment & material synthesis. Surfaces and Materials bridges material synthesis, organization, functionalization, deposition, exfoliation and etching to explore emerging topics such as materials & processes for bio-inspired electronics.

With the aim to create application-centric solutions, INP provides expertise and competences in:

| SURFACE-DIMENSION | MATERIAL-DIMENSION |

|---|---|

Surfaces with tailored adhesion

| Plasma-based synthesis of nanomaterials

|

Surfaces for life-science applications

| Materials for energy technologies

|

| Plasma-cleaned & polished surfaces | |

Bio-sensing surfaces

| Solar materials

|

Functional coatings

| Functional nanocomposites

|

The wide range of applications is based on a number of method-related advantages of plasma technology, such as low thermal load on the components, environmental friendliness, controllability and low direct influence on the basic material properties. Since process costs and simple integration of plasma technology into existing production lines are of great importance, especially in industrial applications, INP offers many processes both at low pressure for highest purity and at atmospheric pressure for short process times.

INP has a long-standing experience in the development of plasma-assisted processes for the refinement of product surfaces, both in the life science sector and in the field of thin-film technology in general. Plasma- and ion-assisted processes span the spectrum from structured material deposition and the targeted adjustment of interface properties to the production of functional layers.