Patients can contract serious infections in hospitals. New technical solutions to improve indoor air quality in highly sensitive clinical areas have been in development for years. Researchers at the INP have now developed an innovative plasma cleaning stage that can be installed in a modular fashion and significantly reduces germs.

The risk of contracting a pathogen in hospital when the body is weakened by the effects of an operation or illness is not insignificant. The German Society for Hospital Hygiene estimates that there are 900,000 infections nationwide every year, resulting in 30,000 to 40,000 deaths. The most common infections are respiratory and urinary tract infections, but wound infections and sepsis also occur. These are not always caused by inadequate hygiene procedures in hospitals; germs are often brought in by patients or visitors.

Against this background, the Leibniz Institute for Plasma Science and Technology (INP) in Greifswald, the medical technology company Pneumatik Berlin and the building services company Haustechnik Bachmann from Steinberg in Saxony have joined forces in the "PlasClean" joint project to develop an intelligent, modular room air system for operating theatres, the centrepiece of which is a special plasma stage. The effectiveness of this already patented decontamination process has been proven in laboratory experiments and in a pilot plant under real conditions. The two-and-a-half-year project was funded by the Federal Ministry for Economic Affairs and Energy.

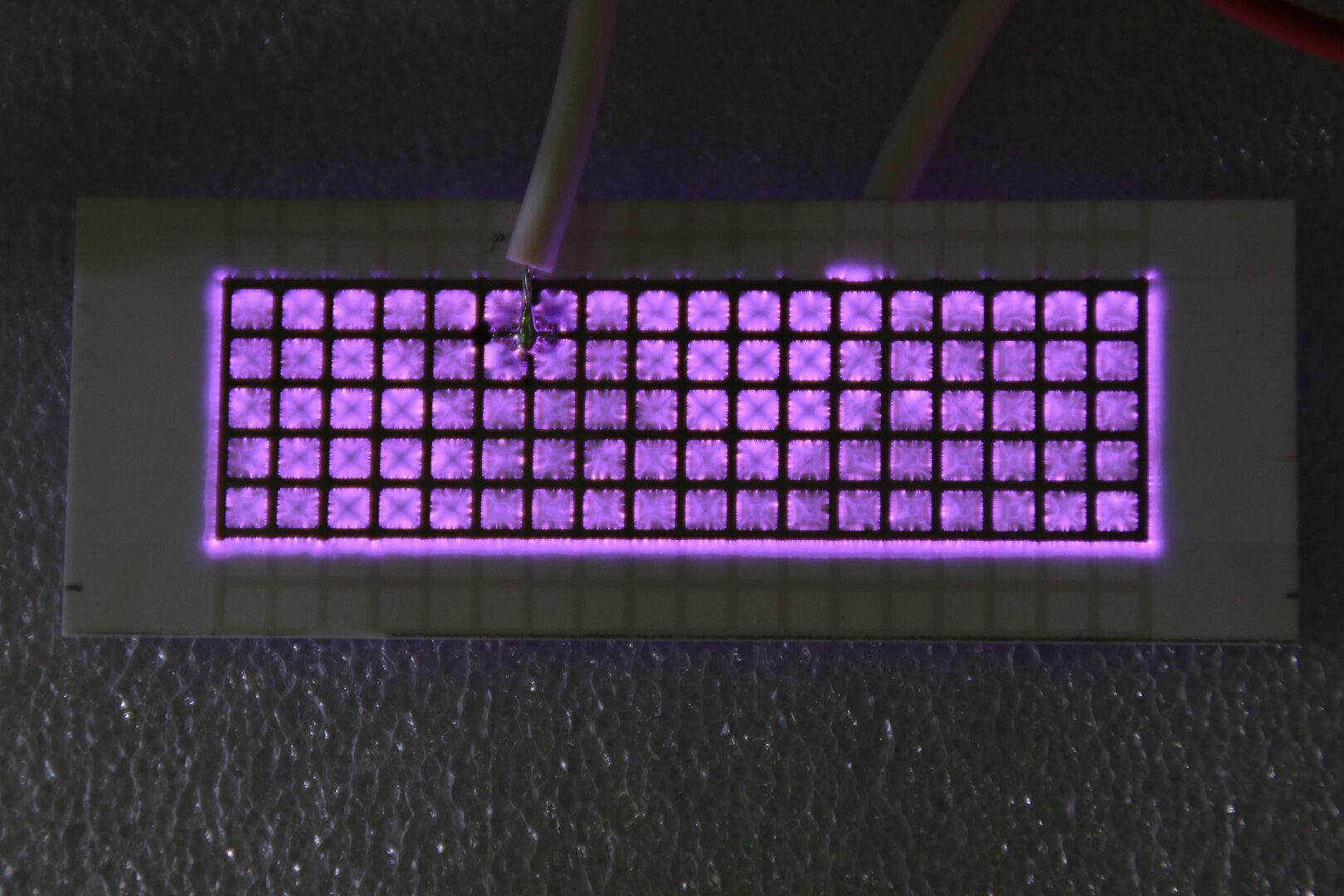

By using modified electrode plates between which dielectrically impeded discharges (see image) are generated, the researchers were able to significantly reduce the level of microorganisms in the room air. Chemical substances can also be broken down in this way. All tests took into account the DIN requirements for intensive care areas: the plasma purified the exhaust air even at the prescribed high air exchange rates.

"Our concept is also forward-looking for other areas of application and can be transferred to clean rooms, laboratories, animal stables or food logistics," says Dr. Manfred Kettlitz, project manager at INP. The plasma stage is scalable, which means that an even greater reduction in microorganisms can be achieved. "However, the technical feasibility must be investigated in further projects," he emphasises. Oliver Siegel, project manager at Pneumatik Berlin, sums it up like this: "By integrating this new system solution, germ-contaminated air inflows could be reliably prevented in rooms with high requirements for low germ levels, such as operating theatres. This makes a valuable contribution to hygiene management in hospitals."

scientific contact person:

Dr. Manfred Kettlitz

Projektleitung

INP Greifswald

Tel. +49 3834 554414

E-Mail:

kettlitz@inp-greifswald.de Oliver Siegel Pneumatik Berlin GmbH PTM

Tel. +49 30 92701071

E-Mail:

siegel@pneumatik-berlin.de