The Leibniz Institute for Photonic Technology (Leibniz IPHT) in Jena and the Leibniz Institute for Plasma Science and Technology (INP) in Greifswald will be working together on a Leibniz research project over the next three years to develop a new process for manufacturing high-performance fibre lasers.

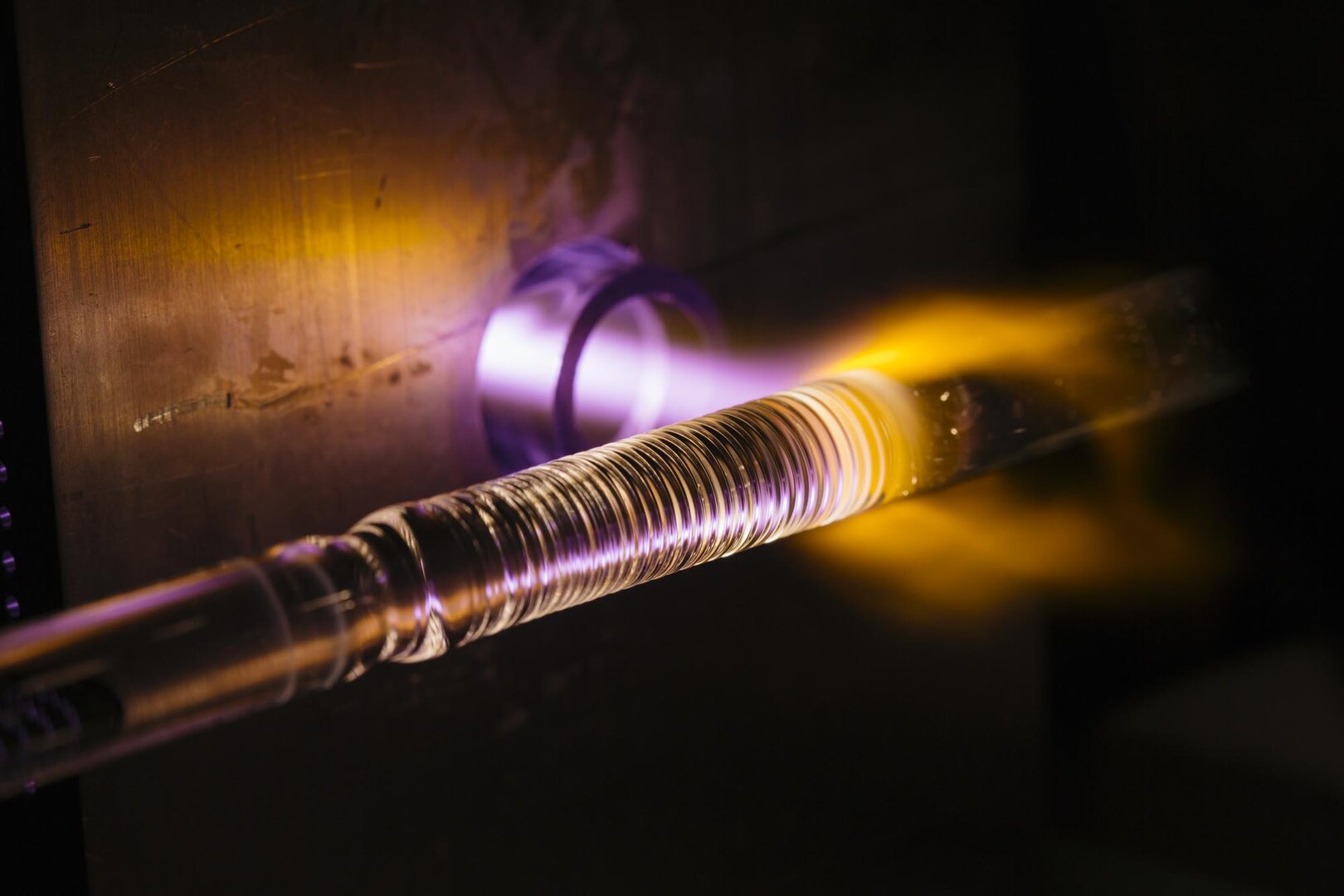

Modern fibre-based high-power lasers are used for large-scale, computer-controlled manufacturing and processing tasks such as welding, cutting and drilling, as well as for surgical procedures in medicine. These lasers are based on optical fibres made of quartz glass mixed with small amounts of different chemical elements. This doping significantly determines the properties and quality of the fibres. Only quartz glasses with exceptionally uniform doping and high purity can achieve the high laser powers and beam qualities required. Until now, the production of such materials has been a challenge. As existing processes are reaching their limits, researchers from Jena and Greifswald are pursuing a new technological approach. Dr Kay Schuster, working group leader for optical fibre technologies at Leibniz IPHT, describes the project goal: “In order to create a new material basis for high-quality optical fibres, we are researching and developing an innovative microwave plasma process as part of the PlasFaser research project. It offers the unique opportunity to adjust many different parameters in the production of doped glasses, thereby creating fibres of a quality that has not yet been achieved.”

Plasma, another state of matter besides solid, liquid and gaseous, exists in nature in the form of polar lights, lightning or under extremely high temperatures in our sun. In the laboratories of INP Greifswald, technical plasmas with lower temperatures are generated and used for applications in the fields of materials, energy, environment and health. During the project, Europe's largest non-university research institution for low-temperature plasmas is investigating the processes that take place during the production of quartz glass and its doping. "Since we are entering completely new territory here, it is essential to understand the chemical and physical processes taking place in plasma in detail . To this end, we are using innovative diagnostic methods at the INP and further deepening our theoretical knowledge using modern modelling methods," explains Dr. Maik Fröhlich, Head of the Plasma Surface Technology Department at INP Greifswald. The partners at Leibniz IPHT transfer the optimal process conditions determined in this way to a process plant where they produce the new glass materials. In the institute's own fibre drawing tower in Jena, the glass body is turned into an optical fibre, whose optical properties and laser efficiency are then investigated.

The project "Development of plasma-based synthesis of novel multicomponent glasses for high-performance optical fibres – PlasFaser", selected by external experts in the Leibniz competition, combines the expertise of two Leibniz institutes in a unique way: over 30 years of research and development work by the Leibniz IPHT on optical glass fibres and the unique scientific expertise of the INP Greifswald in the field of Plasma Science and Technology. The official start of the "PlasFaser" project, which is funded with around 1.2 million euros, was on 1 April 2017.