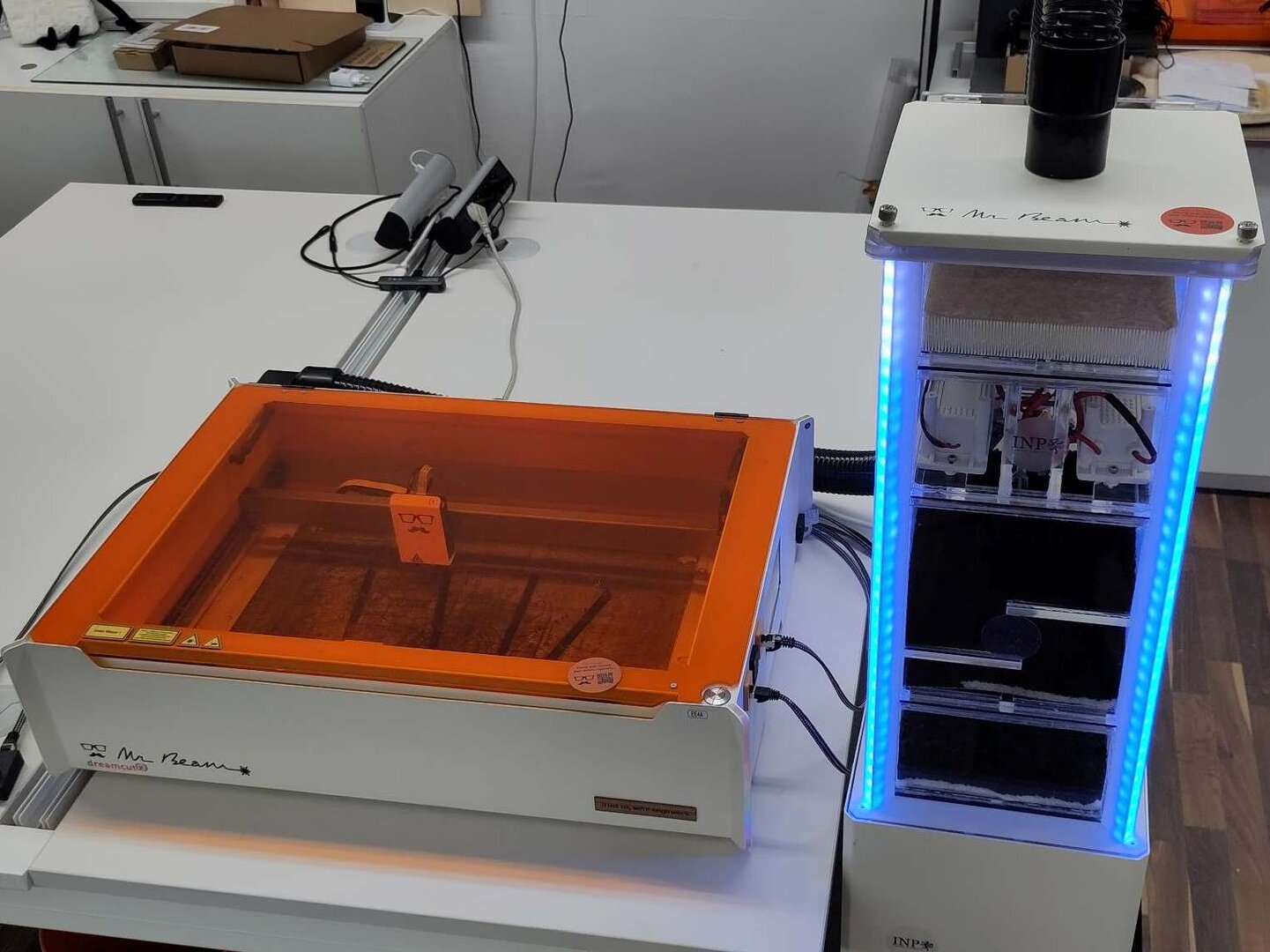

Progress for health: A team from the Leibniz Institute for Plasma Science and Technology (INP) in Greifswald and Mr Beam Lasers GmbH in Munich has succeeded in developing a new type of exhaust air filter for commercial laser cutters. The filter retains the many different gases produced during laser cutting, some of which are hazardous to health or even toxic. This makes working with laser cutters safer for users. The partners in the joint "SafeCutter" project are now presenting the resulting demonstrator at the "26th Laser World of Photonics" in Munich.

In the "SafeCutter" project funded by the German Federal Ministry of Education and Research (BMBF) as part of the "Open Photonik Pro" funding programme, the INP has been working with Mr Beam Lasers GmbH since January 2020 to increase the safety of inexpensive laser cutters. The aim is to enable smaller businesses and private individuals to operate laser cutters more safely. This is because existing laser cutters are designed for industrial use . Safe use requires extensive specialist knowledge and the occupational safety requirements are correspondingly complex, as the operation of these machines produces gases that are hazardous to health.

The technology of the innovative exhaust air filter is based on a combined application of atmospheric cold plasma and a downstream mixed oxide catalyst. Eric Timmermann from INP explains: "For us, plasma catalysis was the most promising approach to simply achieve greater safety for users."

The ozone produced in the plasma is broken down on the catalyst surface and the pollutant molecules are bound with oxygen. This allows the pollutant molecules to adhere better to the catalyst surface and be broken down into harmless compounds. The technology has been systematically investigated in basic experiments for many gases produced during laser cutting. "The results prove that the gases investigated are completely retained," adds Eric Timmermann.

The next steps are promising: the demonstrator developed during the project will now show how the filter performs over longer periods of time and in practice. It is equipped with various sensors that enable the scientists to evaluate its performance.

Following the project, the development team at Mr Beam Lasers GmbH will continue to develop the demonstrator until it is ready for series production. The aim is to integrate it into the next generation of Mr Beam desktop laser cutters. "At Mr Beam, we have been passionate about making laser technology accessible to the general public from the very beginning. The research on the plasma filter marks a significant step forward in our mission to develop safe complete systems. With this concept, we enable our customers to enjoy the full benefits of laser technology without having to compromise on safety. At Mr Beam, we remain committed to safety, quality and user-friendliness, and are increasingly shifting the application of laser technology from industry to the private and small business sectors," explains Teja Philipp, Managing Director of Mr Beam Lasers GmbH.

The demonstrator will be on display to the public at the BMBF's joint stand at the "26th Laser World of Photonics" in Munich from 27 to 30 June 2023. Eric Timmermann will also present further project results in a trade fair presentation on Tuesday, 27 June 2023.

About SafeCutter

The SafeCutter project is researching ways to increase the safety of inexpensive laser cutters so that the technology can be used safely even without prior knowledge. The project partners Leibniz Institute for Plasma Science and Technology (INP) and the Munich-based company Mr Beam Lasers GmbH have joined forces for this purpose. The project is funded by the German Federal Ministry of Education and Research (BMBF) from January 2020 to November 2023 (funding code 13N15206).

The aim of the project is to minimise potential hazards associated with the use of laser cutters through intelligent technology. The focus is particularly on hazards caused by emissions and materials that are not approved for processing. At the same time, manufacturing costs and expenses are to be kept as low as possible, as the high overall costs of laser cutters often make it difficult to use laser technology.